ULTRASONIC THICKNESS MEASUREMENT (UTM)

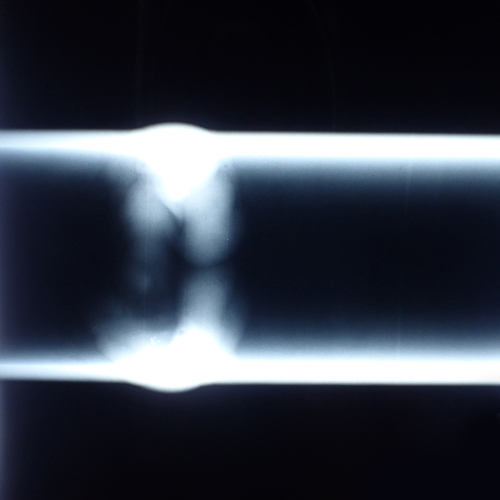

In many industrial maintenance-situations it is necessary to measure the remaining thickness of the metal that is subject to corrosion. Ultrasonic Thickness Measurement (UTM) is a non-destructive testing method used to inspect the local thickness of metallic material and non-metallic materials such as plastics, ceramics, glass and any other good ultrasonic wave conductor. UTM is frequently used to inspect metal thickness in industrial settings.

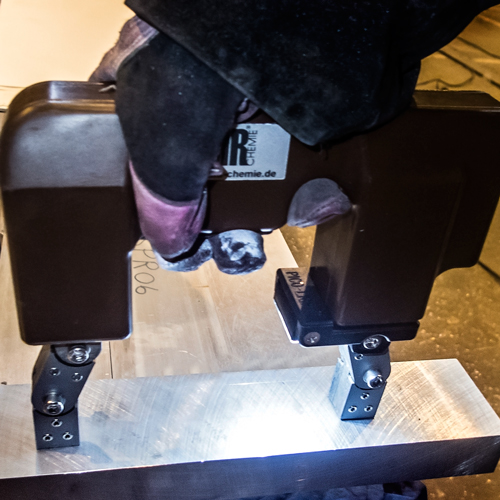

A NDT technician with portable UTM equipment and probes can access steel plating in walls, tanks, decks and the superstructure of ships. Thickness gauges are used that have the ability to measure through painted or coated surfaces and eliminate the thickness of the paint. To ensure effective contact, any visible corrosion is removed and then petroleum jelly or similar substance is applied before pressing the probe against the metal.

The advantages offered by Ultrasonic Thickness Measurement are:

-

Speed, reliability, and versatility.

-

The probe only requires access to one side of the tested part or component.

-

The portable equipment allows for on-site inspection and results are instant.

-

The equipment is easily deployed and does not require laboratory conditions.

-

No cutting or sectioning is required.